About Sarthi Automation

Your Trusted Partner in Smart Automation and Digitalization

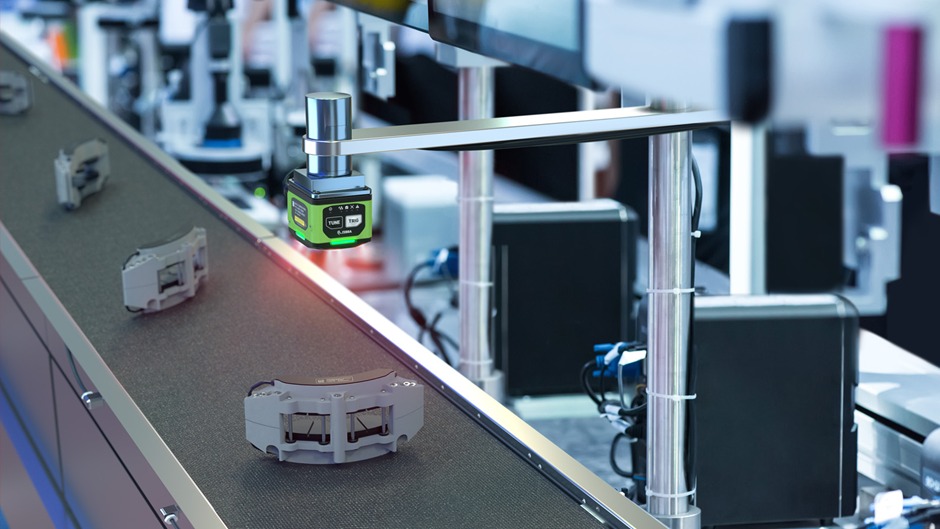

Welcome to Sarthi Automation & Digitalization, your trusted partner in automation and digital transformation. Established with a clear vision to empower businesses with cutting-edge technology, we specialize in delivering smart automation solutions and digital systems that enhance efficiency, reduce operational costs, and accelerate growth.

In today’s fast-paced world, staying competitive means embracing innovation. At Sarthi Automation & Digitalization, we help organizations streamline their workflows, optimize resource usage, and transition from manual to fully digital operations. Whether you’re just starting your automation journey or looking to upgrade your existing systems, our team is committed to delivering tailored solutions that meet your unique business needs.

Establishing Trust

Since 2014

What We Believe In

Our commitment to innovation, quality, and your success.

Our Vision

To empower businesses of all sizes through intelligent automation and cutting-edge digital solutions, transforming the way they operate, innovate, and grow in a fast-evolving digital world.

Our Mission

Our mission is to design and deliver smart automation and digital solutions that help businesses streamline operations, reduce costs, and enhance productivity in a rapidly evolving digital world.

Our Values

At Sarthi Automation, we value innovation, quality, and integrity in every project. We are dedicated to helping our customers succeed through reliable solutions and strong collaboration that drives lasting results.

Team

Our Leadership

At the heart of our company is a team of passionate professionals with a proven track record in automation, robotics, Digitalization, and business operations. Together, they bring strategic vision, technical depth, and execution excellence to every project we deliver.

Randhir Bhosale

Head – Robotics Division

Read more

Randhir Bhosale leads our Robotics Division with deep expertise in industrial robot programming, system integration, and turnkey automation solutions. With years of hands-on experience across welding, material handling, and assembly applications, Randhir plays a key role in developing advanced robotic systems that enhance productivity, precision, and reliability on the shop floor.

Prashant Daud

Head – Digitalization & Controls Division

Read more

Prashant Daud heads the Digitalization and Controls Division, focusing on streamlining manufacturing processes through cutting-edge automation and intelligent controls. He specializes in business process digitalization, PLC, Servo Drive HMI/SCADA and Vision systems, and IoT-based smart solutions. Prashant is dedicated to bridging the gap between traditional manufacturing and Industry 4.0.

Ravikiran Urane

Head – Automation Controls Division

Read more

With extensive experience in PLC, HMI, Drive, Vision and CNC, and industrial automation systems, Ravikiran Urane leads the Automation Controls Division. His strong engineering background and system design expertise ensure the development of robust, scalable, and future-ready automation solutions that meet diverse industry needs.

Avinash Gurav

Head – Business Development, Operations & Project Management

Read more

Avinash Gurav oversees business growth, operational efficiency, and end-to-end project management. He brings strategic insight and disciplined execution to every initiative—from client engagement and proposal development to on-site implementation and post-deployment support. Avinash ensures that every project is delivered with quality, timeliness, and customer satisfaction at its core.

Our Methodology

At Sarthi Automation, we follow a structured and customer-focused methodology to deliver high-quality automation and digitalization solutions. Our approach ensures precision, reliability, and long-term performance support for every project.

Requirement Understanding

Requirement Understanding

Feasibility Study & Solution Design

Feasibility Study & Solution Design

Proposal Submission

Proposal Submission

Design Approval Process

Design Approval Process (DAP)

Offline Development

Offline Development

Client Review & Pre-Approval

Client Review & Pre-Approval

On-Site Implementation & Testing

On-Site Implementation & Testing

Go-Live

Go-Live

Production Support

Production Support