Hello world!

Welcome to WordPress. This is your first post. Edit or delete it, then start writing!

Welcome to Sarthi Automation & Digitalization, your trusted partner in automation and digital transformation. Established with a clear vision to empower businesses with cutting-edge technology, we specialize in delivering smart automation solutions and digital systems that enhance efficiency, reduce operational costs, and accelerate growth.

To empower businesses of all sizes through intelligent automation and cutting-edge digital solutions, transforming the way they operate, innovate, and grow in a fast-evolving digital world.

Our mission is to design and deliver smart automation and digital solutions that help businesses streamline operations, reduce costs, and enhance productivity in a rapidly evolving digital world.

At Sarthi Automation, we value innovation, quality, and integrity in every project. We are dedicated to helping our customers succeed through reliable solutions and strong collaboration that drives lasting results.

Design, development, and commissioning of PLC logic Expertise across Siemens, Allen Bradley, Mitsubishi, Schneider, Delta, and more

Welding, Material Handling, Assembly, Pick & Place Programming for ABB, Fanuc, KUKA, Yaskawa, UR, etc. Simulation and on-site integration

G-Code/M-Code development and optimization CNC machine retrofit and automation Integration with PLC and MES systems

Vision solutions for inspection, measurement, and defect detection Keyence, Cognex, Omron, and AI-based camera systems

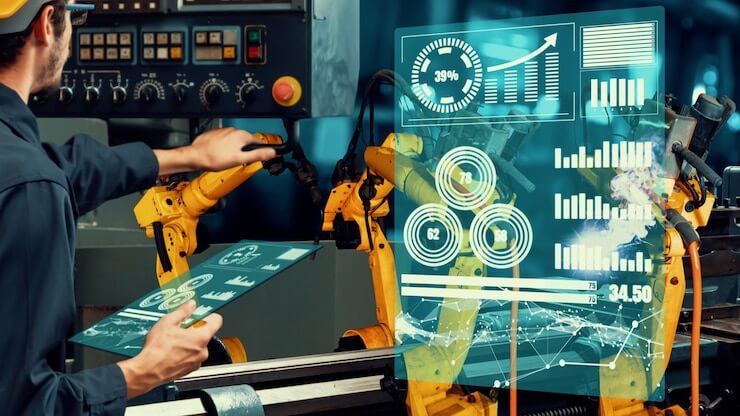

Real-time production visibility Machine connectivity and operations monitoring OEE tracking, alerts, and reports

End-to-End part and process tracking Barcode, QR code, and RFID integration Audit trails for compliance and quality

SCADA/HMI systems VFD, servo, and motor control solutions Turnkey automation of manufacturing and utility processes

Programming and integration of 2-axis / 3-axis gantry systems Applications: material transfer, precision positioning, machine loading/unloading Motion control using servo, PLC, or CNC platforms

Workflow automation for shop-floor and business processes Paperless operations and digital form integration

Real-time machine data acquisition Predictive maintenance using sensor analytics Edge and cloud-based monitoring systems

Machine, process, and ERP data consolidation Custom dashboards for KPIs, OEE, downtime, etc. Data storage and analytics solutions

Web and mobile apps for production, maintenance, and quality Real-time dashboards for insights and decision-making Integration with MES, ERP, and IoT platforms

Process:-Gear machining – Felsomat Machine

System: -S7-1500, Sinamics S120, Sinumerik one 840DSI

Responsibility:- FIS (Factory Information System) testing and verifying, Cycle time optimization

Process: -Crank and Block Machining Line – PARI Machine

System: -S7-1500, Sinamics S120, Sinumerik one 840DSI

Responsibility: - FIS (Factory Information System) testing and verifying, Cycle time optimization

Process: - Crank Forging Plant – Induction Heating Machine

Responsibility: - New Machine launch program | Controls and Standard verification | Operator and Machine safety standard

Verification | Process and Production launch support | PLC FORD standard

Welcome to WordPress. This is your first post. Edit or delete it, then start writing!

WhatsApp us